Back To Newsroom

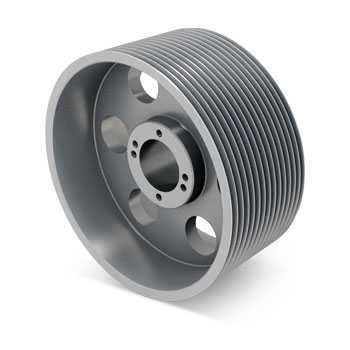

TB Wood's MTO Sheave for Mine Cone Crusher

A major global mining equipment manufacturer needed a replacement sheave for a

cone crusher that broke down at a customer’s mine. Cone crushers utilize a gyrating,

tapered mantle mounted on a vertical spindle that breaks rock material by crushing it

against its concave walls. The rock pieces get smaller as they move past the mantle

and eventually fall through an opening at the bottom of the unit onto a transport

conveyor. The gyrating, center-mounted spindle is powered by a large,

multi-groove V-belt drive that is driven by an electric motor or diesel engine.

The mine was incurring significant losses due to lack of production while the crusher

was out of service. A replacement sheave was needed fast. TB Wood’s was contacted

by its distributor partner based on TB Wood’s reputation as the “large sheave

experts” and its history of delivering in short time frames.

A made-to-order (MTO) solution was manufactured to meet the unique sheave

application requirements. The new 35.5” dia., non-standard 14-groove sheave was

cast using ductile iron instead of standard gray iron due to high drive speed. The

sheave was dynamically balanced at the factory.

As part of its Fastrac program, TB Wood’s was able to manufacture the sheave in just

five business days and ship the completed sheave six business days from the initial

order date. A normal lead-time is 3-4 weeks, or 15-20 business days.

Highlights

- 35.5” made-to-order

(MTO) sheave

- 14 grooves

- Ductile iron

- Dynamically balanced

- Manufactured in five

business days