Back To Newsroom

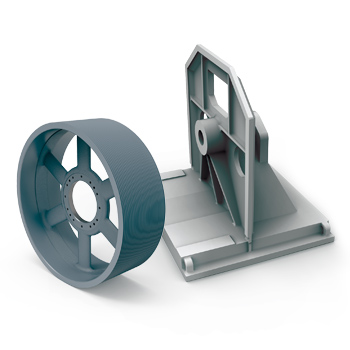

TB Wood's Base Castings and MTO Sheaves for Wood Pellet Mills

A major global manufacturer of biomass machinery and process plants, was looking for

a more reliable foundry for base castings used on its wood pellet mills. The mills produce

uniform wood pellets for use in biomass furnaces. Various machine components are

installed and attached to the 5 ft. wide x 6 ft. high, 6,000 lb. gray iron base casting. The

OEM’s existing casting supplier was having issues with quality and delivery.

TB Wood’s (TBW) has been supplying the OEM with high-quality, Made-To-Order (MTO)

60 in. diameter, 30-groove gray iron sheaves for many years. The sheaves are a key

component on the customer’s belt-driven wood pellet mills.

Based on a history of high product quality and dependable service, the OEM contacted

TBW for a competitive quote and ultimately awarded them the base casting business. In

order to improve casting manufacturability, quality, and machinability, the TBW engineering

team redesigned the molding method and suggested changes to where the casting is parted.

TBW engineers worked with the customer’s engineers to explain the suggested changes

and identify how it would affect the machining vendor. The change required new pattern

equipment, but allowed TBW to improve molding safety and casting quality, while reducing

pattern maintenance and machine stock on the casting.

TBW also worked with the machining vendor to identify areas of concern and help with

casting lineup for machining. This allowed the machining vendor to reduce their price,

which provided additional savings for the customer. The customer and their machining vendor

are very pleased with the quality and timely delivery of the new TBW castings.

Highlights

- Made-To-Order (MTO)

60 in. diameter,

30-groove, Class 35 gray

iron sheaves

- 5 ft. wide x 6 ft. high,

6,000 lb., Class 30 gray

iron base castings

- Re-engineered, economical

casting design saved

manufacturing and

machining costs