Ductile Iron Design Advantages

- Superior castability and machinability compared to steel

- Can be made for a lower cost than steel

- Has superior mechanical properties compared to gray cast iron

- Has an excellent strength-to-weight ratio

- Castings can weigh 6% less than dimensionally identical steel parts

Ductile iron was invented in the mid-twentieth century and is a modern iteration of cast iron (also known as “gray iron”). Gray iron and ductile iron have contrasting physical properties caused by differences in their microstructures. The graphite and carbon contained in gray iron occur as flakes.

Gray iron exhibits positive compressive load capabilities; however, it is brittle with virtually no elongation so it is not recommended for tensile and shock loading applications.

Ductile iron, on the other hand, can be twice as strong as gray iron. It has considerable elasticity, impact resistance and high yield strength. The superior mechanical properties of ductile iron can be attributed to its unique graphite shape. The graphite within ductile iron occurs as spheroids, allowing the material to elongate significantly under tensile stress, while still ensuring excellent machining properties compared to steel of similar mechanical properties.

Overall, ductile iron has steel-like mechanical properties with the castability, machinability, and corrosion resistance of gray iron.

During the casting process or heat treatment, the matrix structure around the graphite must be carefully controlled to create different grades of ductile iron. In order to create the desired matrix or microstructure for a specific grade of ductile iron, the foundry must make minor compositional changes.

The most common ductile iron matrices are:

- Ferrite: a low strength, pure flexible iron. This matrix features high impact resistance and

good machinability, but has poor wear resistance.

- Pearlite: a layered mixture of ferrite and iron carbide. This high-strength matrix is relatively

hard with some ductility. It also has good wear resistance, good machinability, and

moderate impact resistance.

In order to obtain the desired mechanical properties to meet individual customer specifications, different ratios of ferrite and pearlite are required. For example, in ASTM A536 grades 65-45-12 and 80-55-06, the ferrite component provides the elongation performance to the material that could not be achieved with a fully pearlite matrix. Inversely, the pearlite component provides the tensile and yield strength that could not be achieved with a fully ferritic matrix.

Another property that is critical to the performance of ductile iron is graphite nodularity percentage. Nodularity percentage is a measurement of ductile iron, taken using a microscope, that determines the degree of roundness in graphite nodules. As it is the graphite’s nodular shape that gives ductile iron its superior strength and ductility. Frequent tests are required during manufacture to verify that the desired graphite shape is maintained.

Graphite percentage is a measurement of cast iron using a microscope, that identifies the relative surface area of a polished face of iron occupied by graphite versus that occupied by iron matrices (ferrite, pearlite, etc.) This measurement is useful to ensure that the graphite is not taking up too little or too much of the casting volume which would be detrimental to desired mechanical properties.

Ductile iron has greater strength and ductility than gray iron. These properties make it ideal for use in a wide variety of industrial applications, including:

- Shock load applications such as rock crushing

- Pump housings

- Machine frames for the wind-power industry

- V-belt sheaves and rope pulleys

- Gear boxes

- Compressors

- Pipe and pipe components

- Automotive components

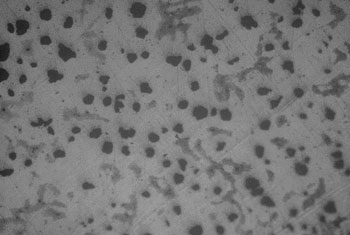

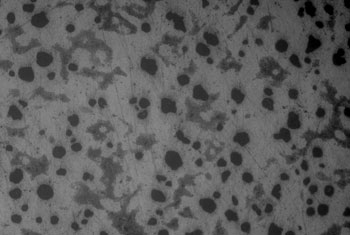

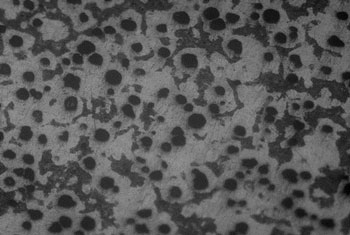

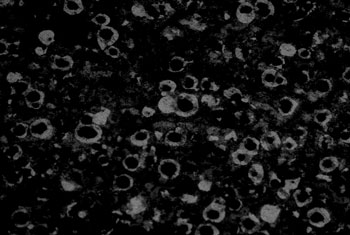

The images below depict average microstructures for each grade of ductile iron produced

by TB Wood’s. The light areas indicate ferrite, while the dark areas represent graphite and pearlite.

Grade 60-40-18

This ductile iron grade is a nodular iron with an

almost full ferrite matrix. This microstructure is

achieved through annealing and offers excellent

ductility and impact strength.

Grade 65-45-12

This ductile iron grade contains nodular graphite in a matrix of ferrite with a smaller amount of pearlite.

The ferritic structure provides excellent machinability along with optimal impact strength and fatigue properties.

Grade 80-55-06

This ductile iron grade contains nodular graphite in a matrix of ferrite and pearlite. The pearlite/ferrite

structure yeilds high wear resistance and strength when compared to a ferrite grade of ductile.

Grade 100-70-03

This ductile iron grade contains nodular graphite

in a matrix of pearlite with very small amounts of

ferrite. This pearlite structure maximizes strength

and wear characteristics in the “as-cast” ductile iron.